WELDING COURSES

Welding course & what is taught in welding

Shielded Metal Arc Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material (parent metal). Pressure may also be used in conjunction with heat, or by itself, to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized.

Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often an industrial process, welding may be performed in many different environments, including in open air, under water, and in outer space. Welding is a hazardous undertaking and precautions are required to avoid burns, electric shock, vision damage, inhalation of poisonous gases and fumes, and exposure to intense ultraviolet radiation.

Additional training is available to graduates of the Basic Plate and Sheet Metal Welding who wish to take an operator qualification test for AWS structural code work, and to graduates of the Pipe Welding Course who wish to take similar tests for ASME (vertical-up) or API (vertical down) code work. Welders with equivalent experience may also qualify for this training.

Flux-Cored Arc Welding Self-Shielded/Gas-Shielded

Classes are available to companies and/or individuals who want to practice welding techniques for passing an operator qualification test or procedure qualification test. This course is also designed to give the proper application skills to an instructor for in-plant training of FCAW-S and/or FCAW-G (UltraCore.

Stick Welding

This is a process that uses a flux coated electrode to form the weld, applications of stick welding is in mining, manufacturing, construction, metal and steel fabrication among other

This is a process that uses a flux coated electrode to form the weld, applications of stick welding is in mining, manufacturing, construction, metal and steel fabrication among other

Stick welding is technically defined as “Shielded Metal Arc Welding”. The term “stick welding” is a common slang term that the welding industry has adopted because the electrode that welds the metal comes in the form of a “Stick”.

The simplest explanation of how stick welding works. Stick welding is a form of welding that uses electricity to melt a metal filler rod/electrode/stick (electrode is the proper term) that melts both the metal joint and electrode all at once to fuse two pieces of metal together and fill the joint with filler metal at the same time.

MIG Welding

Mig welding is a process in which an electric arc forms between an electrode and a metal workpiece, heating the metal and causing them to melt and be joined. it is used extensively in manufacture of space vehicles.

Mig welding is a process in which an electric arc forms between an electrode and a metal workpiece, heating the metal and causing them to melt and be joined. it is used extensively in manufacture of space vehicles.

MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas. The technical name for it is gas metal arc welding (or GMAW), and the slang name for it is wire welding.

The MIG process enables the home-hobbyist, artist, farmer/rancher, motorsports enthusiast or DIY welder to make most types of fabrication and maintenance/repair welds on material from 24-gauge up to 1/2-inch thick. In addition to flexibility, many people turn to MIG welding because they've heard that it's an easy process to learn. Some claim it's no harder to use than a glue gun. While it's not quite that simple, it is true that most people can become competent MIG welders by following some basic advice.

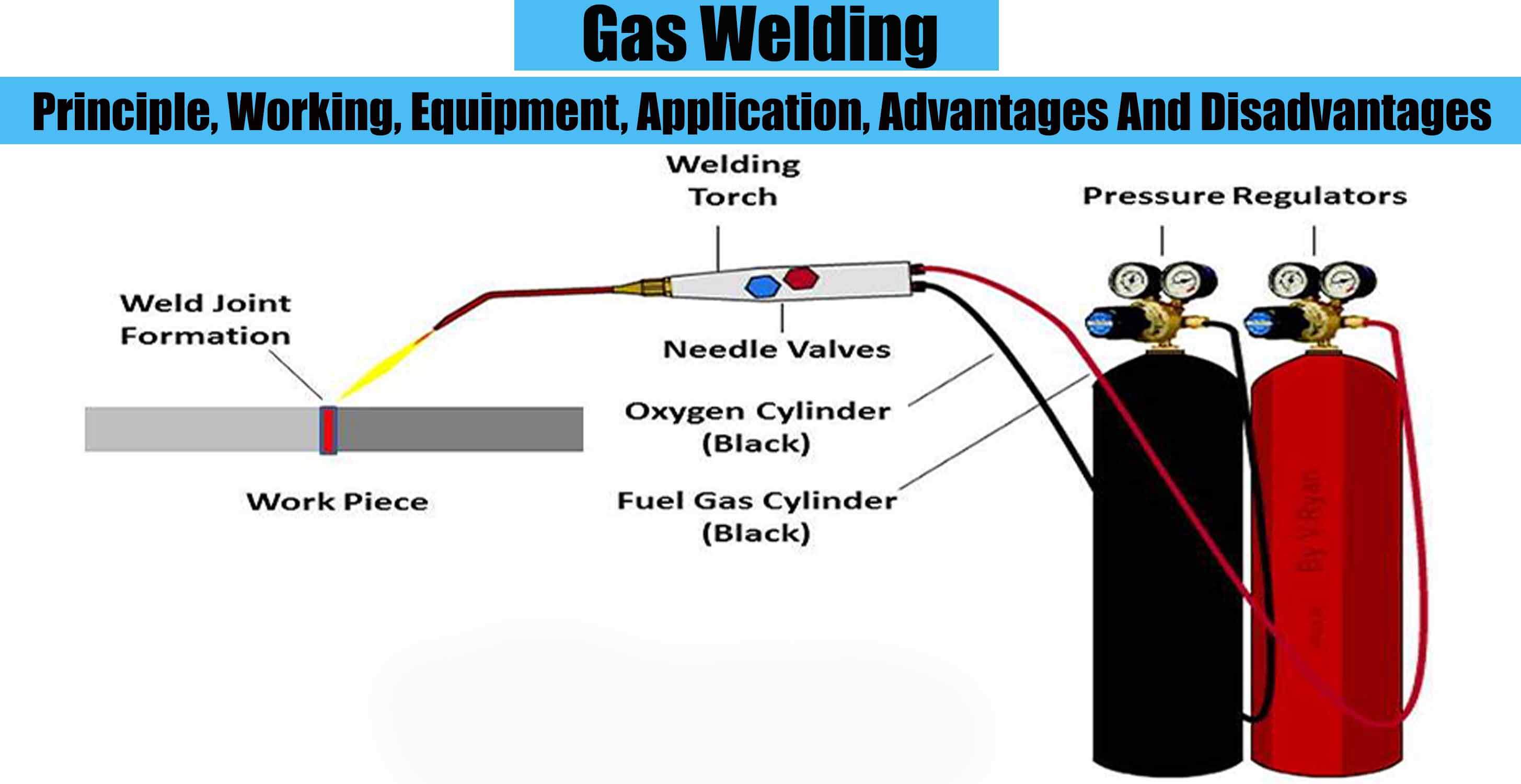

Gas Welding

Gas welding involves metal joining process in which the ends of process to be joined are heated at their interface by producing coalescence with one or more gas flames (such as oxygen acetylene) with or without the use a filter metal, also used in cutting torches to cut and separate metal and others.

Gas welding involves metal joining process in which the ends of process to be joined are heated at their interface by producing coalescence with one or more gas flames (such as oxygen acetylene) with or without the use a filter metal, also used in cutting torches to cut and separate metal and others.

It’s a cheap, transportable and flexible form of welding, that doesn’t require any electrical equipment, and is capable of cutting, welding and brazing most metals. In this article we’ll give you a full guide for understanding the basics to gas welding.

Gas Cutting

Gas cutting it consists of preheating the metal to be cut to its oxidation temperature

Gas cutting it consists of preheating the metal to be cut to its oxidation temperature

Process of Gas Cutting:

Apart from using hacksaw, power saw, chisels, etc. for metal cutting operation, gas or oxygen cutting is extensively used now-a-days in industry.

Oxy-fuel cutting (OFC) is similar to ox fuel welding except that:

(i) It uses oxidizing flame.

(ii) It uses gas-cutting torch.

The process consists of preheating the metal to be cut to its ignition (oxidation) temperature, i.e., above 870°C in case of steel.

The preheating is done by oxy-acetylene gas flame, which is supplied from surrounding openings of the cutting torch. When this temperature is attained, a jet of high-pressure oxygen from a central opening of the cutting torch is directed on the red-hot metal.

Welding Training Courses

All these welding courses are real career investment as there is lot of demand of qualified welders for big metal industries all over the world.

- ARC Welding

- Argon welding

- CO2 welding

- Aluminium welding

- Gas Welding

- Gas cutting

- Flux Core Welding

- Boiler Making

- Pipes Fitting

- Plumbing

- Steel welding

- Fitter & Turner

NB: We also have long term welding courses i.e.

Level 2 welding courses at 3months and Level 3 at –6months

Courses include:

Boiler making…Level 2 & 3

Argon welding.. level 2 & 3

Arc welding….Level 2 & Level3

Co2…l2 & l3

Aluminium welding….Level2 & Level3

Steel welding Level2 & Level3

Please Note:

Accommodation is Available and free for those coming from far and outside South Africa!!